Enjoying a front row seat as the industrial internet of things (IIoT) turns into a practical reality via tech transfer.

When it comes to ensuring economic growth and development, there are few better places to invest than academic research. The annual AUTM Licensing Activity Survey, which reports on private sector licensing of intellectual property originating from university research, continued an upward trend even through the great recession. Patents, new product sales of licensed technology, new products, new spin-off companies and the number of spin-off companies still active at the end of the year were all still strong as the rest of the economy struggled.

I was thinking about the importance of tech transfer this last week as I attended the 33rd Advisory Board Meeting of the Center for Intelligent Maintenance Systems (IMS). Having attended a number of these events over the years, I have enjoyed seeing the work of the various postdoctoral researchers advance over the years, as well as seeing them mature as confident professionals.

This year, it seemed like many were conducting research near and dear to IFS’s heart, including:

- Deep learning inspired prognostics using big data

- Advanced analytics for robust energy efficiency in HVAC systems

- Maintenance network design for joint preventive maintenance and spare part logistics systems

- A framework for dynamic maintenance scheduling optimization for wind farms

- Maintenance knowledge creation by association rule learning with failure event data

- Camera as a sensor for asset management

It certainly makes sense for IFS to support research like this that is in our wheelhouse. But as the AUTM data suggests, technology transfer is vital to a healthy society and may be something corporations should support just on general principle.

The initial licensing revenue and new business spin-offs are only one way in which tech transfer drives the economy. But when this technology is truly disruptive and widely applicable for industrial organizations, that disruption can, like ripples on a pond, drive benefit across sectors like:

Dynamically driving advances across these industry spaces is exactly what the IMS, as a tech transfer outfit at the University of Cincinnati, has done. Their work has focused on, as the name implies, industrial maintenance but increasingly has expanded to manufacturing automation and artificial intelligence (AI).

A founder and mentor

IMS, due in large part to the vision and drive of founder Dr. Jay Lee, has launched not only spin-off companies like the newly-minted predictive maintenance group Predictronics. The Cincinnati-based academics collaborate actively with those at the University of Texas at Austin and the University of Michigan. The center also attracts the involvement of major organizations like P&G, GE Aviation, Rexroth Bosch Group, Gleason Corporation and others that leverage the resulting research in their organizations and employ the researchers as interns and in permanent positions.

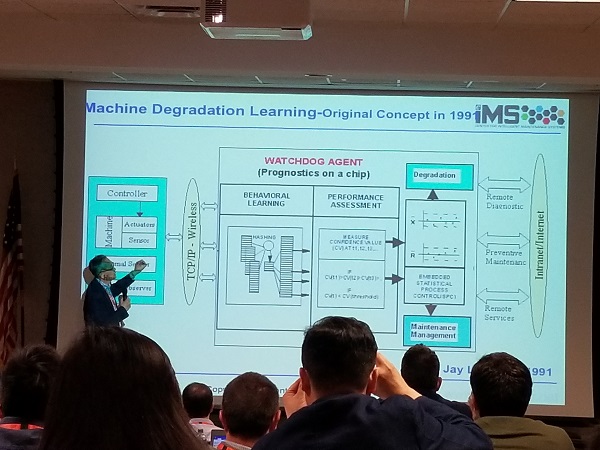

IFS has been involved since about 1999 when Dr. Lee was with the University of Wisconsin-Milwaukee and wanted to start an intelligent maintenance systems group. It is hard to believe that at that juncture, industrial maintenance was largely focused on break-fix modalities, or at most, basic calendar-based maintenance. Dr. Lee saw that modern control systems were generating a tremendous amount of data and that this data could be harnessed to improve machine reliability and improve productivity, safety and company performance.

Perhaps Dr. Lee could sense the direction of the industry, the zeitgeist, and facilitated it. Or perhaps he gave the industry a kick in the pants that got us further down the road towards the IIoT. It could be that the University of Cincinnati recognized the potential of Dr. Lee’s work to a greater extent than academic researchers in my hometown of Milwaukee and lured him away, much to the chagrin of those of us left behind.

One thing is for sure, though–IMS has been a major contributor to IIoT and predictive and condition-based maintenance. They are the only entity to have received an unprecedented five-year grant from the National Science Foundation grant (NSF). This is because IMS is the number one program NSF funds in terms of economic impact generated, with 280 times economic impact based on dollars invested. IFS does not invest much with IMS, but we support their gatherings of researchers and industrial partners. We get to attend, of course, which keeps us on the cutting edge of current IIoT research.

IFS was a sponsor of the first workshop 17 years ago in Milwaukee and has stayed involved with these watershed gatherings, up to and including this year’s event, hosted by IMS’s industry partner MAZAK Corp. in Florence, Ky.

A common mindset

IFS got its start when a group of engineering students graduated from their local university and started a company, in our case to develop a maintenance management system for a nuclear power plant. That was significant, important work, and the goal was to make something good and beneficial that was not there before. So, we see in these researchers kindred spirits who want to make the world better. But we also, in the efforts of IMS, see tremendous contributions to our shared efforts to enable industrial organizations of all kinds to realize the true benefits of IIoT.

Learn more about IFS’s approach to corporate social responsibility.

Do you have questions or comments about IIoT?

We’d love to hear them so please leave us a message below.